Advanced Technologies for Embroidery and Perforations in Luxury Interiors for Cars, Yachts, and Private Jets

- Posted by Flavio Marini

In the world of luxury interiors, such as those for automobiles, yachts, and private jets, precision and quality are essential. We have been leaders in industrial embroidery since 1986, with a particular focus on the automotive sector, where attention to detail and customization capabilities make the difference. We utilize highly advanced machinery that combines embroidery, multicolor stitching, and perforation in a single process, offering ideal solutions for those seeking exclusivity and high quality.

esempio foratura e imbottitura 3d

Millimetric Precision and Reliability for Complex Designs

Thanks to our advanced facilities, we can perform operations with stitching precision up to 0.1 mm, ensuring perfect alignment between quilting lines and perforations. This level of accuracy is crucial to prevent misalignments in designs and achieve a flawless finish, which is essential for luxury interiors.

esempi di ricami per interni

Available Perforations

To customize interiors, we offer a wide range of perforations, ideal for applications on leather and other high-quality materials, with the following available sizes:

- Circular Hole: 0.8 mm, 0.9 mm, 1.0 mm, 1.1 mm, 1.2 mm, 1.3 mm, 1.4 mm, 1.5 mm, 1.7 mm, 1.8 mm, 2.0 mm, 2.5 mm

- Square and Diamond Hole: 1.5 x 1.5 mm

- Triangular Hole: 1.7 mm side punch

This variety allows us to meet both stylistic and functional needs, giving our clients the opportunity to create exclusive and customized designs.

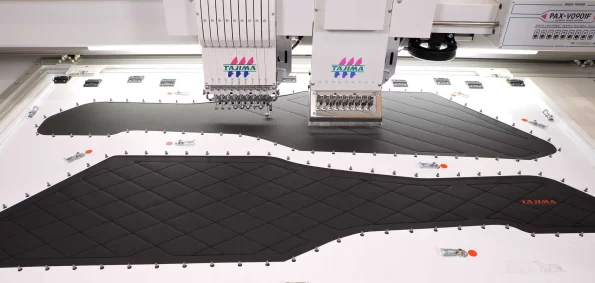

esempio imbottitura e trapuntatura

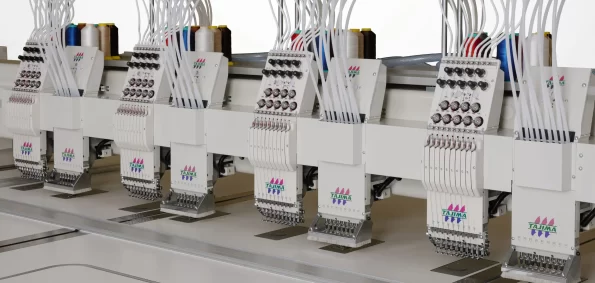

Efficiency and Flexibility in Multicolor Production

Our machinery allows configurations of up to 9 colors and 4 operating heads, enabling simultaneous work on four different products with distinct styles. With a large working area of up to 1,000 mm x 1,200 mm, we can handle operations on large pieces, such as car seats and interior panels.

Deformation Control and 3D Finishes

Our technology enables perforation, stitching, and embroidery in a single step, preventing deformations that often occur during material transport and storage between different processing stages. The DCP (Digitally Controlled Presser Foot) technology ensures a uniform three-dimensional finish on materials like leather and polyurethane, eliminating loose threads and enhancing the final quality.

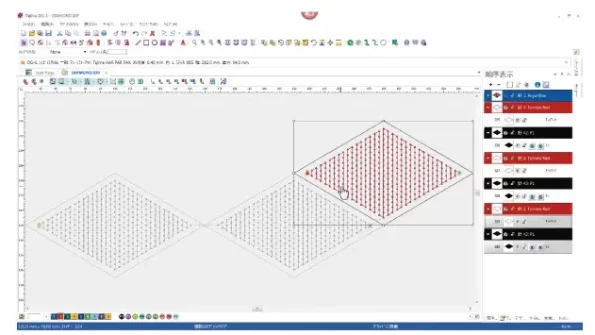

software creazione ricami per interni automotive

Software and Accessories for Maximum Creativity

Thanks to dedicated software, we can convert data from Illustrator and CAD to design complex patterns without the need for traditional molds, reducing both time and costs. Additionally, our facilities include accessories that optimize the process:

- Auto Bobbin Checker (ABC): Monitors the remaining thread in the bobbin, preventing stitching defects.

- Bobbin Changer: Allows pre-loading of up to three bobbins, minimizing machine downtime.

- Safety Sensors: Such as the Beam Sensor, which stops the operation if an operator approaches, ensuring a safe working environment.

macchina da ricamo per interni automotive

Our decades of experience and advanced technologies allow us to meet the customization and quality demands of the most discerning clients. We offer tailor-made solutions for luxury interiors, combining precision, efficiency, and superior quality to create unique and highly valuable projects.

For any inquiries, feel free to contact us info@ricamificiomarini.it .

0 comments on Advanced Technologies for Embroidery and Perforations in Luxury Interiors for Cars, Yachts, and Private Jets